born from the heart of earth

mining

Our mining experiences are primarily based in Sri Lanka, where ethical mining is still largely practiced using traditional methods. Gem pits in Sri Lanka vary by depth:goda illama(shallow) pits are circular, whileyati illama(deep) pits are rectangular. In deep mining, the pits are reinforced with timber and planks, typically from rubber wood and areca nut trees. Miners first remove non-gem-bearing materials, then dig down to reach gem-bearing gravel. The soil is brought to the surface using muscle power or winches. Pumps are used to keep the pits dry, while candles provide light and act as a safety measure for harmful gases. In some cases, miners dig horizontal tunnels, calleddonava, to reach the gems. Timber supports the pit walls, especially in wet conditions. Shallow pits are only a few meters deep, but deep pits can exceed 100 meters. Traditional mining tools such as shovels, pickaxes, and hammers are still commonly used.

Gem SORTING

In Sri Lanka, traditional gem sorting involves a meticulous, hands-on process. After gem-bearing gravel is extracted from the pits, it is brought to the surface and carefully washed to separate the gems from the surrounding soil and impurities. Miners then sift the gravel using sieves or pans, sorting the stones by size and type. Skilled workers visually inspect the material, identifying valuable gems like sapphires, rubies, and other precious stones. The process relies on experience and knowledge, as miners can distinguish gemstones based on their color, shape, and texture. This traditional method, passed down through generations, ensures that each gem is carefully assessed before being further processed or sold.

trading

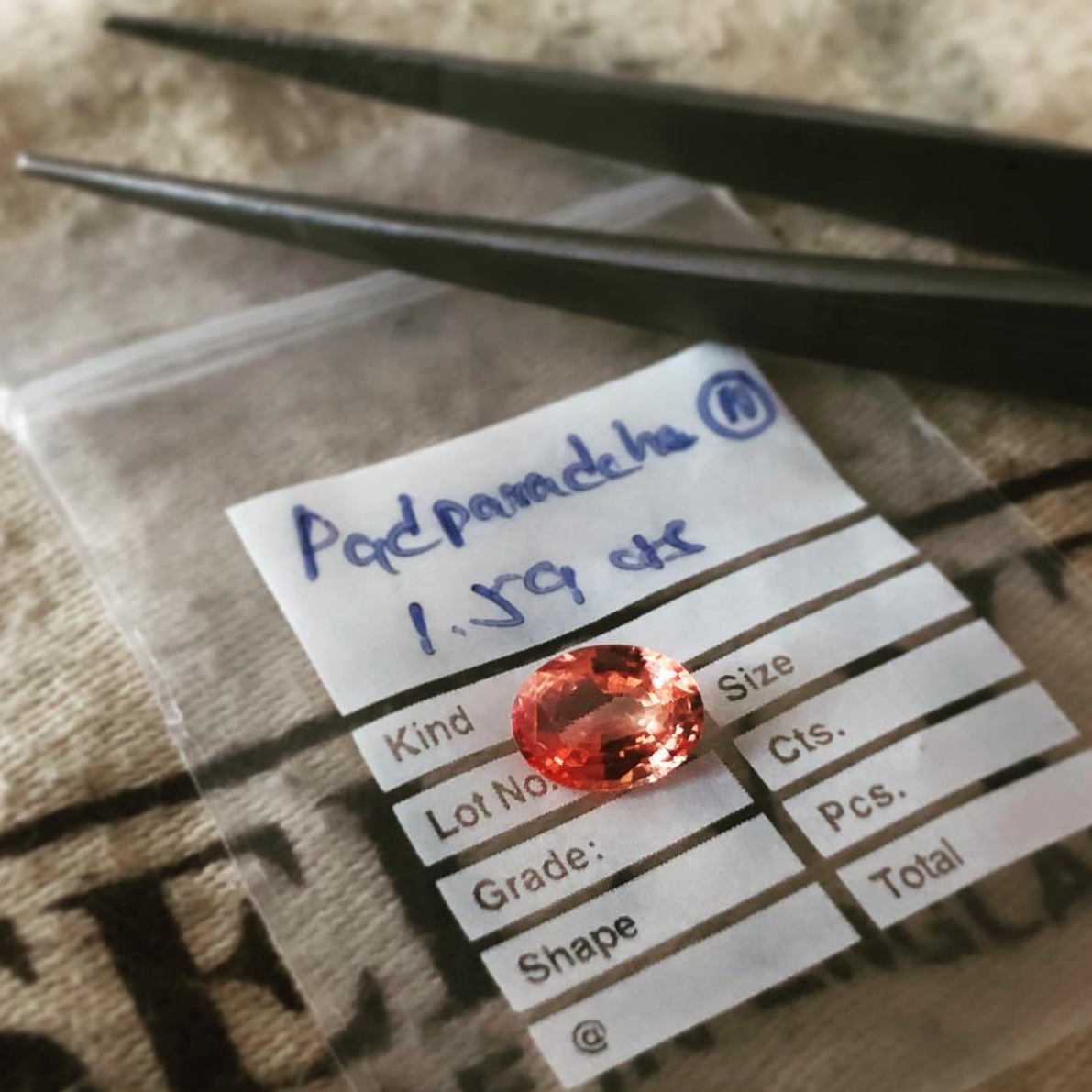

In Sri Lanka, the sale of rough gemstones typically takes place in vibrant local markets or specialized gem exchanges, where traders, gem dealers, and buyers gather. After being mined and sorted, rough gems are either sold directly by miners or through intermediaries. The stones are often sold based on their size, color, and quality, with prices determined through negotiation. Many rough gemstones are purchased by local dealers or exporters who then cut and polish them for the international market. The gem trade in Sri Lanka is highly regulated, with laws in place to ensure fair practices and transparency, though informal transactions are still common in some areas.

Heating

After rough gemstones are sorted and purchased, they are often heated to enhance or evenly distribute the color, a process commonly done using traditional methods in Sri Lanka. Known as "thermal treatment," this technique involves heating stones, especially sapphires, in a furnace or open flame at controlled temperatures to improve their color and clarity. This centuries-old practice is carefully carried out to avoid damage, as excessive heat can harm the gem. Many Sri Lankan gem dealers still use this method to enhance the appearance of gemstones before they are cut or sold.

PRE-FORMing

Pre-forming of gemstones is the process of shaping rough stones into a basic form before they are fully cut and polished. This stage involves removing excess material from the rough gem using tools like saws, grinders, or dopping sticks. The goal is to create a preliminary shape that maximizes the gem's potential, preserving its quality and value. Pre-forming helps determine the final shape and size of the gemstone while also allowing for adjustments to enhance its appearance. Skilled gem cutters carefully inspect the stone during this stage to ensure it will yield the best results in the final cutting and polishing process.

CUTTING & POLISHING

Gem cutting and polishing is the process of transforming a rough gemstone into a finished, sparkling piece. Cutting involves shaping the gem to enhance its brilliance and symmetry by carefully faceting it with precision tools. The gem is cut into a specific shape, such as round, oval, or emerald cut, depending on its type and quality. After cutting, the gem is polished to smooth its surfaces and bring out its shine. This is done using abrasive materials and polishing wheels to achieve a glossy, reflective surface. The process requires great skill and attention to detail to maximize the gem's natural beauty and value.

Spectrum of colours

Learn about coloured gemstones

Spectrum of colours

Why Coloured Stones?

Spectrum of colours

Introduction to Sapphires

Spectrum of colours

Sapphires: Mine to market

Spectrum of colours

Sapphires treatments

Spectrum of colours

Other coloured gemstones

Spectrum of colours

Introduction To Spinels

Spectrum of colours

How to pick your colored stone